Cheap filament splicing method

Cheap filament splicing method

Here's a method I've developed to splice filaments almost to perfection without any tools. It's basically the Teflon tube method for cheapskates who don't want to buy Teflon tubing 🙂

First of all, prepare a 2" x 2" (50mm x 50mm) -ish piece of white paper and a straighten a piece of filament that will serve as a mandrel:

Roll up the paper into a tube around the piece of straightened filament as tight as you can. The hard bit is to start rolling: the paper needs to be really snug against the filament to start with.

Once it's started right, it's easy. Roll it up all the way nice and flat. The bit of filament inside should fit inside the tube with quite a lot of friction if you did it right:

You can also wet it a few times with your tongue and it will stay in one piece without holding it. Ex-smoker's habits die hard 🙂

Cut the ends of the filaments to splice together with a sharp bevel:

Carefully thread the ends into the paper tube so they meet halfway:

They should go in with some force but they should slide smoothly. If you feel any roughness, you've snagged the paper inside and it won't work, so you should start over.

Heat up the center of the tube at 250C to 260C while ramming the filaments into each other firmly, but not so firmly as to collapse the paper tube, until you feel them "go" and melt into one another:

I use a SMD rework station because you can apply heat as much as you want and the paper only browns a bit, even if you overdo it grossly. It takes about 30 seconds for the heat to diffuse through the paper and for the filaments to melt fully. It's doable with a lighter too while pushing the filaments together with one hand, but it's less convenient of course.

Then unwrap the paper: some paper should stay stuck to the splice:

Clean up the splice by running a sharp knife along the splice all around. It's pretty quick, the paper isn't terminally fused to the filament:

Voila: perfect splice!

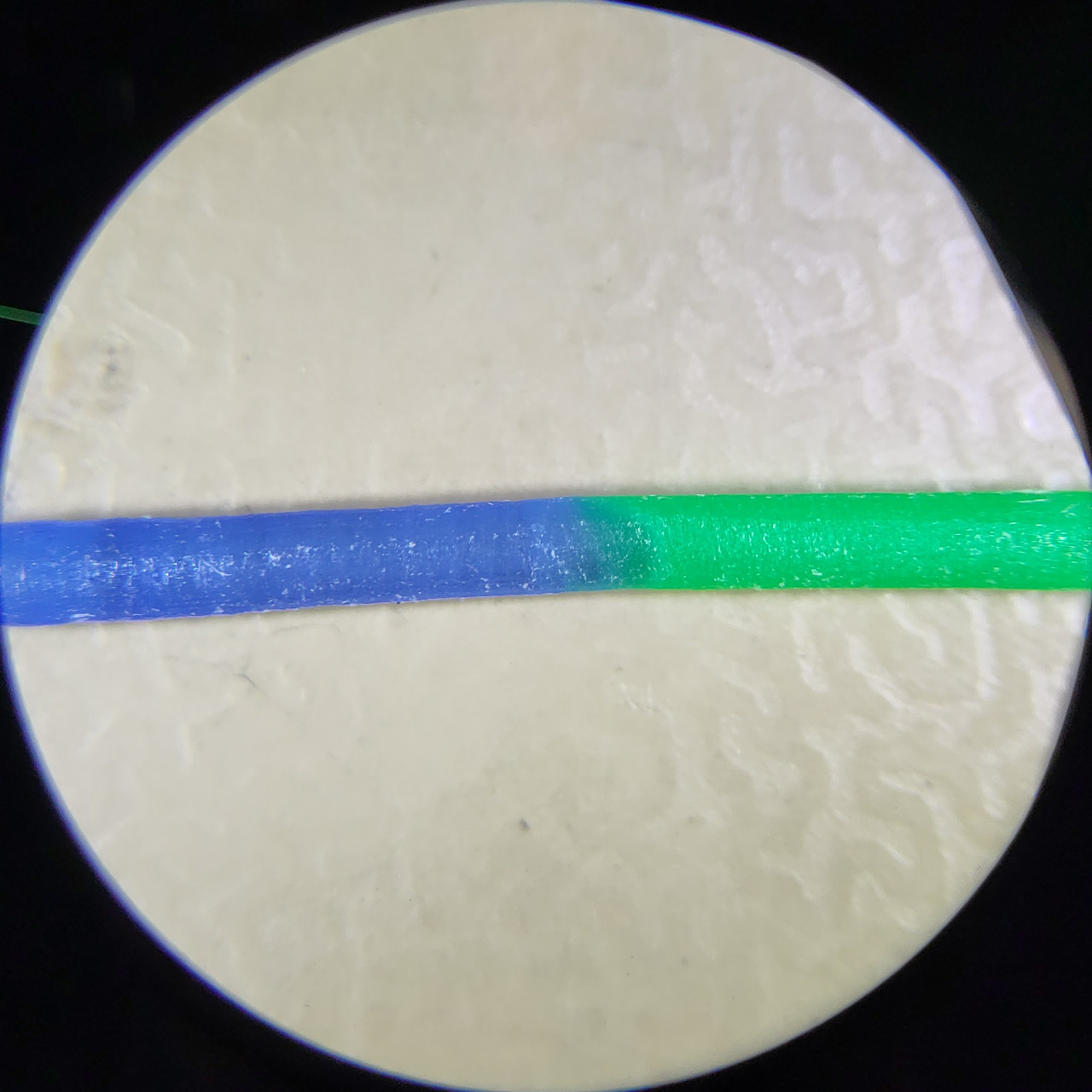

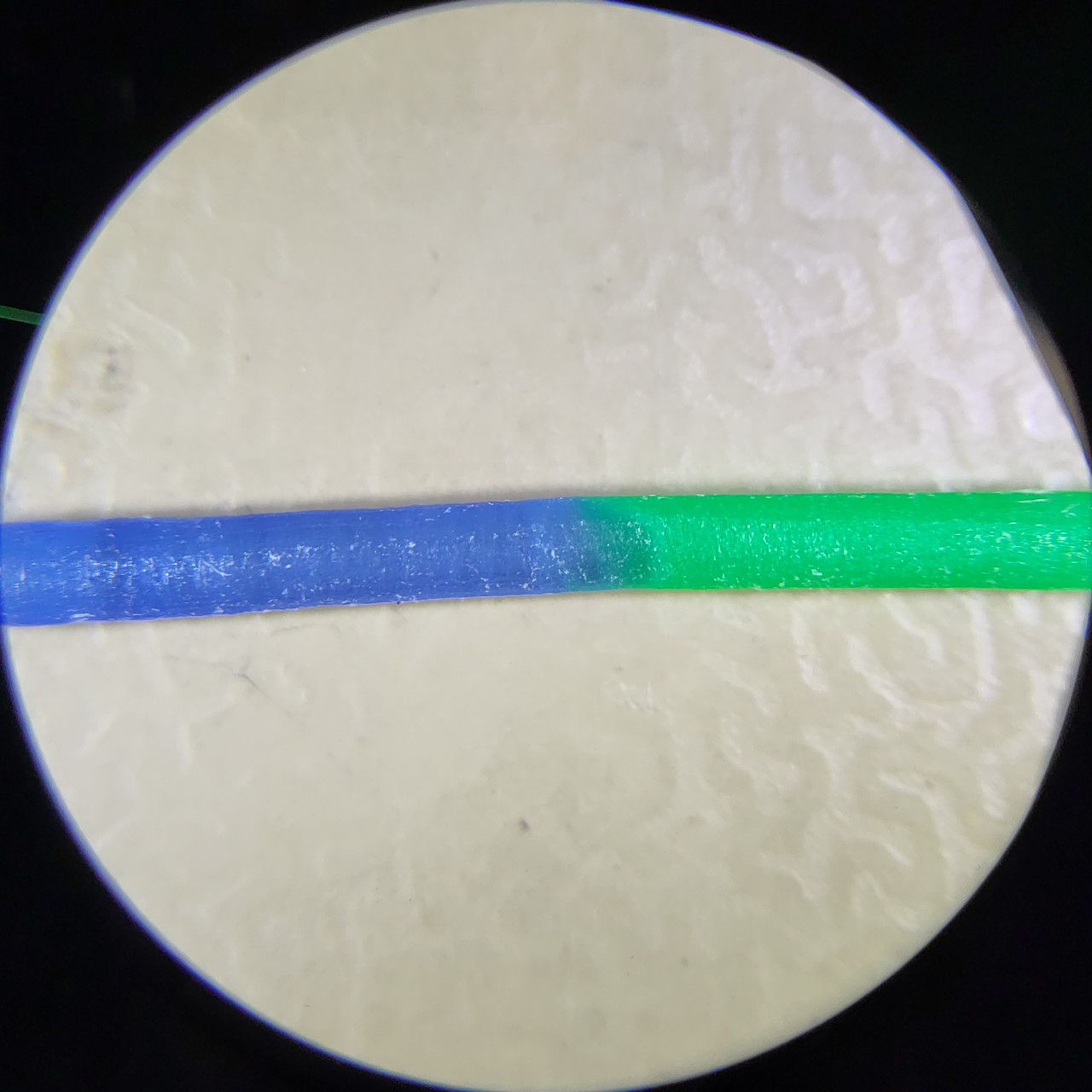

And here, seen under a microscope: